The Ohio DFSP-5 form, which outlines a Drug-Free Safety Program, shares similarities with the Occupational Safety and Health Administration (OSHA) Form 300A. Both documents are centered around workplace safety, but the OSHA Form 300A specifically focuses on recording and summarizing work-related injuries and illnesses. They both encourage reflection on current safety practices and aim for improvement but through different lenses: the DFSP-5 with a proactive approach to drug-free policies and the OSHA Form 300A through tracking and mitigating injuries.

Another document similar to the Ohio DFSP-5 form is the Employee Health and Wellness Program Plan, which, like the DFSP-5's focus on employee health promotion, seeks to foster a healthier work environment. Both documents prioritize the health and well-being of employees, albeit from different angles. The Health and Wellness Program focuses more on broader health initiatives and personal well-being, while the DFSP-5 includes this as part of a broader safety and health culture effort.

The Risk Management Plan is analogous to the Ohio DFSP-5 form in its objective of identifying, assessing, and controlling risks within an organization. However, while the DFSP-5 is narrowly focused on safety and health, particularly around drug-free workplace initiatives, a Risk Management Plan encompasses a wide range of potential risks, including financial, operational, and strategic risks. Both documents require systematic assessment and action plans to mitigate identified risks.

Corporate Social Responsibility (CSR) Reports share common ground with the Ohio DFSP-5 form by emphasizing ethical operational practices, with the CSR reports focusing on a company's social, environmental, and economic impact. Both documents highlight the importance of management commitment and employee involvement, albeit with the DFSP-5 concentrating specifically on safety and health improvements as part of its ethical considerations.

The Business Continuity Plan (BCP) resembles the Ohio DFSP-5 form through its focus on preparedness and continuity of operations during and after a disaster or crisis. While the BCP takes a broad approach, covering all aspects of business recovery, the DFSP-5 targets safety and health process improvements, specifically in the context of maintaining a drug-free workplace. However, both plans involve identifying potential threats, assigning responsibilities, and outlining steps for recovery.

The Employee Orientation Program often includes components that mirror parts of the Ohio DFSP-5 form, such as safety and health training and education, albeit in a more generalized context. New employee orientation programs introduce participants to workplace safety, policies, and culture, while the DFSP-5 provides a structured framework specifically for enhancing safety and health through drug-free policies.

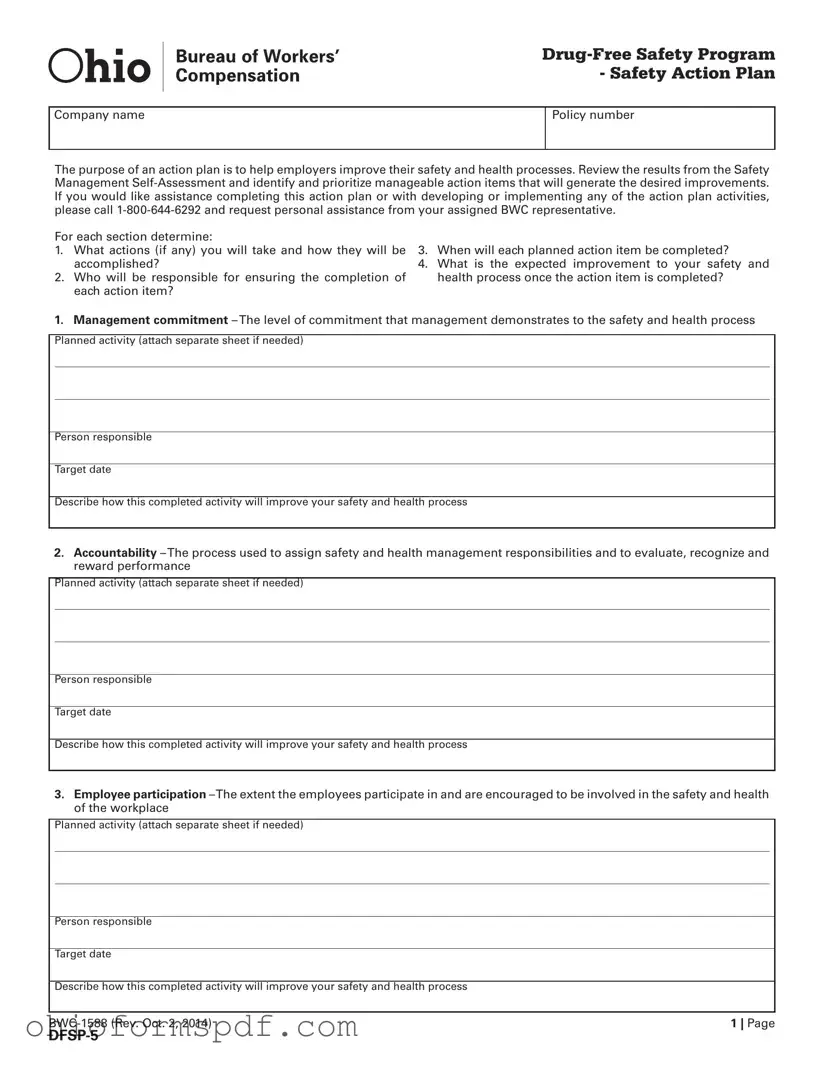

Workplace Safety Policy documents, similar to the Ohio DFSP-5 form, outline the procedures and policies designed to preserve the safety and health of employees. Both documents detail specific roles, responsibilities, and expectations to maintain a secure working environment. However, the DFSP-5 places a unique emphasis on the drug-free aspect of workplace safety, tying in substance abuse prevention as part of the broader safety culture.

Finally, Quality Management System (QMS) documentation shares similarities with the Ohio DFSP-5 form in their mutual goal of continuous improvement. Both sets of documents establish systems and processes aimed at improving effectiveness and efficiency, though QMS documents typically focus on product quality and customer satisfaction, while the DFSP-5 is focused on safety and health outcomes, particularly in maintaining a drug-free workplace.